Press release

Friction Shims Market to Surge with 7.2% CAGR, Projected to Hit US$ 1,443.4 Million by 2034: Fact.MR Report

The global friction shims market was valued at US$ 673.4 million in 2023 and has been forecasted to expand at a noteworthy CAGR of 7.2% to end up at US$ 1,443.4 million by 2034.Thin friction shims are used between the contact surfaces in mechanical assemblies to increase friction and improve grip. Most of the shim materials manufactured from stainless steel, aluminum, and copper provide resisting friction forces against slippage, bearing load, and transmitting torque in highly stressed conditions. Friction shims serve for vast applications in automotive, aerospace, and industrial machinery to ensure stability, longevity, and precision.

Friction Shims Market Analysis by Material Type

Material selection plays a critical role in the performance and durability of friction shims. Stainless steel remains the dominant material due to its exceptional strength, corrosion resistance, and ability to withstand high temperatures. Aluminum-based friction shims, on the other hand, are increasingly preferred in lightweight automotive and aerospace applications where weight reduction is a priority without compromising performance. The ongoing research in advanced alloys and surface treatments is also expected to further enhance the wear resistance and friction coefficient of shims, opening new avenues for their adoption in high-performance machinery.

Applications Across Automotive and Industrial Sectors

The automotive and engine technology segment continues to be the largest end-use application of friction shims. They are critical in transmission systems, engine components, and braking assemblies to prevent slippage, reduce wear, and maintain mechanical precision. Meanwhile, friction shims are also increasingly deployed in automation and handling systems. Industrial robotic arms, conveyor mechanisms, and precision assembly lines benefit from shims that ensure accurate torque transmission and minimal operational loss. Growing demand for automation and robotics is expected to accelerate the adoption of friction shims in these industrial applications over the forecast period.

Full Market Report available for delivery. For purchase or customization, please request here - https://www.factmr.com/connectus/sample?flag=S&rep_id=10501

End Use Industry Dynamics

Construction and automotive sectors are the principal end-users of friction shims. In construction machinery such as cranes, excavators, and loaders, shims help maintain stability under heavy loads and high-stress operations. In the automotive sector, friction shims enhance drivetrain efficiency and improve the durability of engine components. Other sectors, including aerospace and general industrial machinery, are witnessing gradual adoption as manufacturers increasingly prioritize equipment longevity, precision, and safety. The multi-industry applicability of friction shims underscores the robustness of market growth in the coming decade.

Regional Insights

Regionally, North America and Europe are expected to maintain strong demand due to the presence of mature automotive and industrial manufacturing sectors. Asia Pacific is projected to be the fastest-growing market, driven by rapid industrialization, expanding automotive manufacturing, and government incentives supporting advanced machinery adoption. Meanwhile, the Middle East and Africa are gradually emerging markets with potential growth opportunities as infrastructure and industrial projects increase across these regions.

Browse Full Report: https://www.factmr.com/report/friction-shims-market

Recent Developments and Competitive Landscape

The friction shims market is witnessing strategic moves by key players to enhance market share and product portfolios. Companies are investing in R&D to develop high-strength, lightweight shims and alloys suitable for extreme operating conditions. Collaborations and partnerships with automotive OEMs and industrial machinery manufacturers are also on the rise to ensure customized and application-specific solutions. Leading players are focusing on geographic expansion and production optimization to meet growing regional demand, particularly in Asia Pacific and emerging markets.

In addition, innovation in surface treatments, coatings, and precision manufacturing techniques is providing competitive differentiation. Companies that invest in sustainable and cost-effective manufacturing practices are likely to gain a competitive edge, as industries increasingly demand materials that are not only high-performing but also environmentally responsible.

Conclusion

With expanding applications across automotive, industrial automation, and construction sectors, the friction shims market is poised for significant growth between 2024 and 2034. Material innovations, strategic partnerships, and regional market expansion are key drivers that will shape competitive dynamics, ensuring that friction shims continue to be a critical component in mechanical assemblies worldwide.

Check out More Related Studies Published by Fact.MR:

Glycol Pumps Market

https://www.factmr.com/report/glycol-pumps-market

Contactless Elevator Market

https://www.factmr.com/report/contactless-elevator-market

Heat Staking Machine Market

https://www.factmr.com/report/heat-staking-machine-market

Cargo Nets Market

https://www.factmr.com/report/cargo-nets-market

Contact:

US Sales Office

11140 Rockville Pike

Suite 400

Rockville, MD 20852

United States

Tel: +1 (628) 251-1583, +353-1-4434-232

Email: sales@factmr.com

About Fact.MR

We are a trusted research partner of 80% of fortune 1000 companies across the globe. We are consistently growing in the field of market research with more than 1000 reports published every year. The dedicated team of 400-plus analysts and consultants is committed to achieving the utmost level of our client's satisfaction.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Friction Shims Market to Surge with 7.2% CAGR, Projected to Hit US$ 1,443.4 Million by 2034: Fact.MR Report here

News-ID: 4197165 • Views: …

More Releases from Fact.MR

Organic Pigments Market Transformation Report 2036: Innovation Trends, Sustainab …

The global Organic Pigments Market is poised for robust transformation through 2036, driven by expanding industrial demand, heightened sustainability imperatives, and rapid innovation in colorant technologies. The market is forecast to expand significantly as manufacturers, formulators, and end-users pursue environmentally compliant, high-performance pigmentation solutions across coatings, plastics, and inks applications.

Market Growth Trajectory & Key Metrics

The organic pigments industry is currently valued in the billions and is projected to maintain a…

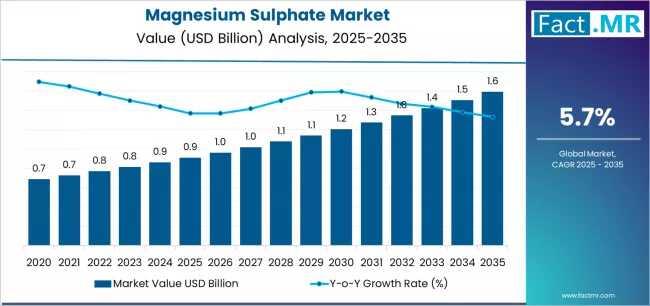

Magnesium Sulphate Market Valuation, ROI Potential & Long-Term Growth Prospects …

The global Magnesium Sulphate Market is poised for robust expansion over the next decade, reflecting sustained demand across agriculture, pharmaceuticals, industrial processes, and emerging end-use applications. The market is expected to grow from an estimated USD 0.91 billion in 2025 to USD 1.59 billion by 2035, registering a compound annual growth rate (CAGR) of 5.7% over the forecast period.

This growth translates to roughly USD 0.68 billion in incremental revenue by…

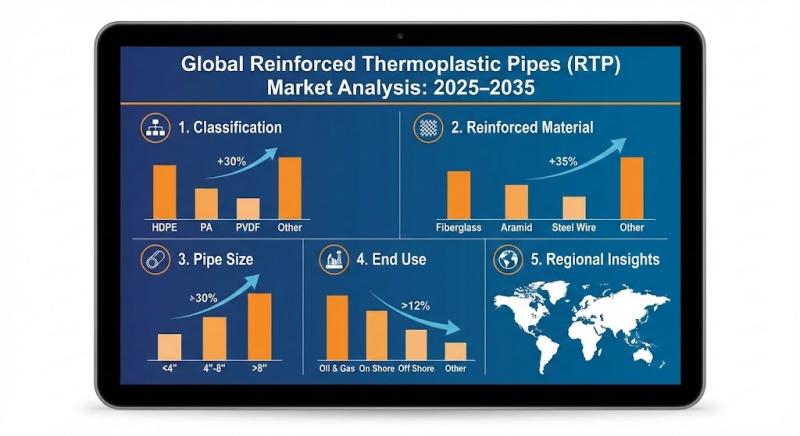

Global Reinforced Thermoplastic Pipes Market Dynamics 2026-2036: Risk Assessment …

The global Reinforced Thermoplastic Pipes (RTP) market is poised for sustained growth through 2036, driven by rising demand for corrosion‐resistant, lightweight pipeline solutions across oil & gas, water management, and industrial infrastructure. The market is projected to grow from an estimated USD 385.6 million in 2025 to USD 610.4 million by 2035, achieving a CAGR of 4.7 % over the forecast period.

Market Drivers & Growth Trajectory

The demand for RTPs is…

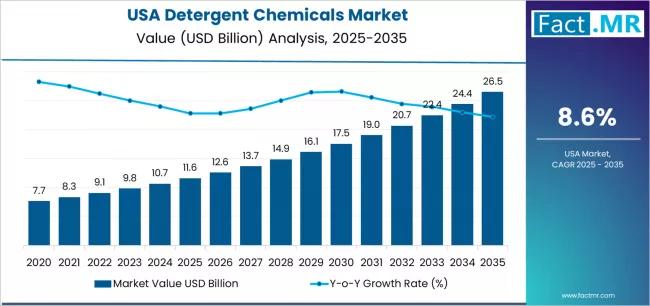

2036 USA Detergent Chemicals Industry Intelligence Report: Technology Shifts, De …

The demand for detergent chemicals in the United States continues to grow steadily, supported by rising hygiene awareness, expansion of household and industrial cleaning activities, and continuous innovation in formulation technologies. Detergent chemicals form the backbone of laundry detergents, dishwashing products, industrial cleaners, and institutional hygiene solutions, making them essential across residential, commercial, and industrial sectors.

In the U.S., strong consumer focus on cleanliness, coupled with stringent hygiene standards in healthcare,…

More Releases for Friction

Friction Products and Materials Market Is Booming Worldwide | Tenneco, Carlisle …

The latest research study released by AMA on the Friction Products and Materials Market offers over 181 pages of analysis on business strategies employed by key and emerging industry players. It provides insights into current market developments, landscape, technologies, drivers, opportunities, market outlook, and status. The market study is segmented by key regions driving market growth. The Friction Products and Materials study combines qualitative and quantitative market data, primarily collected…

Friction Materials Market Analysis By Top Keyplayers - ABS FRICTION CORP., Akebo …

The "Friction Materials Market" is expected to reach USD xx.x billion by 2031, indicating a compound annual growth rate (CAGR) of xx.x percent from 2024 to 2031. The market was valued at USD xx.x billion In 2023.

Growing Demand and Growth Potential in the Global Friction Materials Market, 2024-2031

Verified Market Research's most recent report, "Friction Materials Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2023-2030," provides an in-depth…

Friction Modifiers Market, By Type (Organic Friction Modifiers and Inorganic Fri …

Data Bridge Market Research analyses that the friction modifiers market will witness a CAGR of 9.7% for the forecast period of 2022-2029. Friction modifiers market report analyses the growth, due to accelerating application of friction modifiers in advertising and promotions of various brands.

Friction modifiers, also known as boundary lubrication additives, are oil-soluble chemicals used in lubricants as transmission and internal combustion engine additives. These lubricants are used in machine components…

Friction Product Market 2027 Worldwide Analysis on Revenue, Segmentation and Key …

MARKET INTRODUCTION

Friction products are used to produce friction in order to reduce the velocity or stop the movement of a particular object. Friction is the resistance which opposes the movement of object. Friction products cover wide range of pads, linings, blocks, rolls, sheets, clutches etc. Commonly used materials in friction based products are paper (cotton or cellulose fiber and phenolic resin mixture), elastomerics, graphitics, sintered metal ceramics, advanced fibers and…

Global Friction Products and Materials Market 2018 Top Players are: ABS Friction …

Friction material is used in every-day mundane applications such as automotive brakes and clutches to commercial and industrial applications.

According to this study, over the next five years the Friction Products and Materials market will register a xx% CAGR in terms of revenue, the global market size will reach US$ xx million by 2024, from US$ xx million in 2019. In particular, this report presents the global market share (sales and…

GMP Friction Products Develops Friction Materials for Wind Energy Turbine Market …

Brakes Stop and Hold Wind Turbine Blades for Emergency, High Winds or Maintenance

AKRON, OHIO (January 19, 2012) – GMP Friction Products, working with wind turbine manufacturers and the suppliers to the OEM market, has developed high-speed friction brake materials designed to reduce rotational speed below maximum value or bring the blades of a wind energy turbine to a standstill. Following more than 1,000 braking sequence tests, they have developed friction…